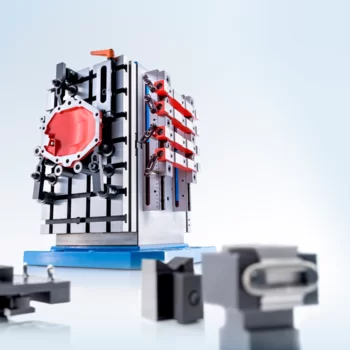

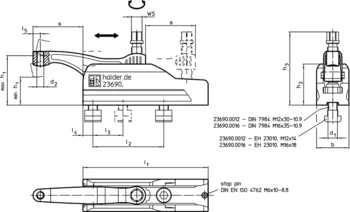

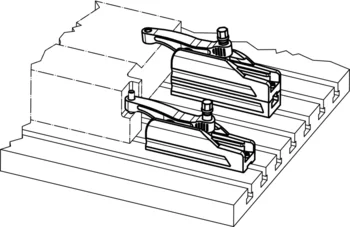

23690.0016 - Compact Clamps

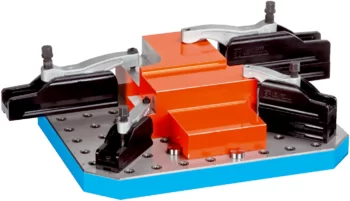

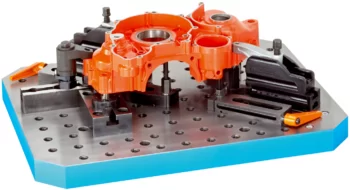

The compact clamps are all purpose clamping elements. Due to the self-locking tension lever application can either take place in horizontal or vertical position in both, machined and raw workpieces.

Features:

- Exact and position precise clamping

- Easy, universal handling

- High clamping force at low tightening torques, abrasion-resistant due to tension lever with bearings

- Continuous, large clamping area

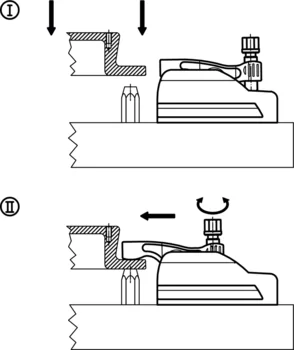

- Tension lever entirely retractable for hindrance-free exchange of workpieces

- Tension lever with locating thread for various clamping elements, e.g. ball-ended thrust screws (EH 22700. - EH 22720.), self-aligning pads (EH 22730. / EH 22740.) etc.

- Large adjusting range at constant clamping force

- Continuous increase of the clamping range by height adapters 23690.0112 / .0116

- Easy and flexible mounting options

- Corrosion-resistant

- Resistant to dirt and chips

This article 23690.0016 - Compact Clamps / (d1: M16) is one variant of the article group Compact Clamps (EH 23690.)

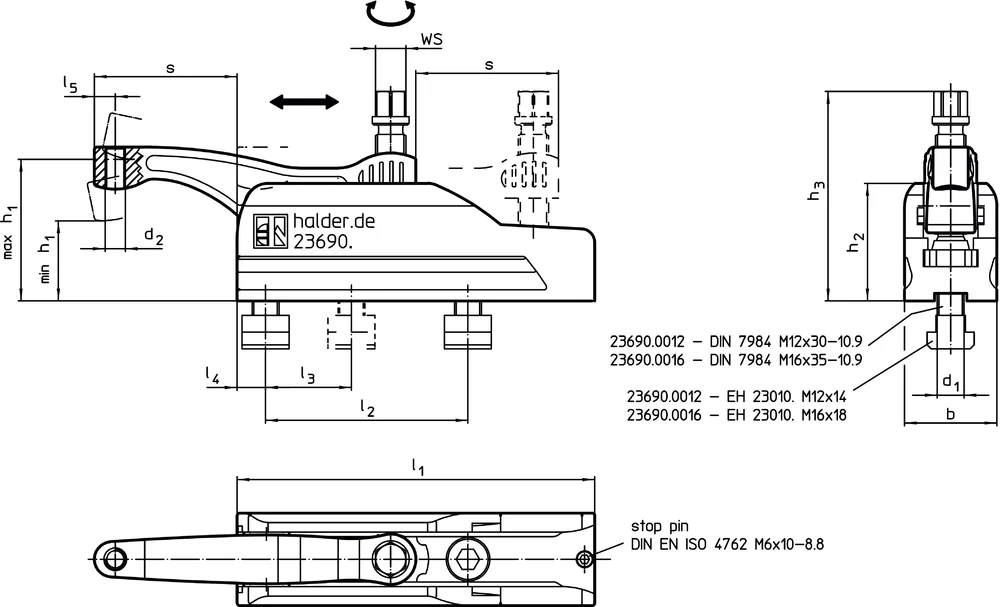

- System: L16

- d1: M16

- d2: M12

- h1 min.: 47 mm

- h1 max.: 85 mm

- h2: 70 mm

- h3: 126 mm

- s max.: 85 mm

- l1: 213 mm

- l2 +1: 120 mm

- l3: 50 mm

- l4: 17 mm

- l5: 12.5 mm

- b: 55 mm

- WS: 18 mm

- Clamping force max.: 25 kN

- Tightening torque max.: 75 Nm

- Weight: 4000 g

Material

Body

- Heat-treated steel, black coated

Tension lever

- Heat-treated steel, tempered, silver coated

Assembly

Assembly and Set-Up:

- Take out stop pin ISO 4762-M 6 x 10.

- Move back and take out tension lever.

- Tightening by 2 screws with internal hexagon (included in supply volume).

- Place tension lever in sliding rail and then insert.

- Tighten stop pin ISO 4762 - M 6 x 10.

Operation

Clamping Process:

- Slide tension lever to clamping position.

- Clamping is made via a hexagon collar screw.

- Releasing is done in reverse order.

RoHS compliant

Contains lead - compliant according to exceptions 6a / 6b / 6c.

Contains SVHC substances >0,1% w/w

Contains lead - SVHC list [REACH] as of 23.01.2024.

Contains Proposition 65 substances

Lead can cause cancer and reproductive harm from exposure

https://www.P65Warnings.ca.gov/

Free from Conflict Minerals

This product does not contain any substances designated as "conflict minerals" such as tantalum, tin, gold or tungsten from the Democratic Republic of Congo or adjacent countries.