Load-handling devices for threads: plug it in instead of screwing it in!

Exceptional carrying force with maximum safety and minimum effort

The lifting pins engineered by Erwin Halder KG have established themselves as a reliable tool for lifting and holding individual loads - not least because of their unparalleled ease of use. Now unveiling threaded lifting pins, the company is expanding their range of load-handling equipment. These lifting elements have been developed specifically for existing threads. They are just as quick and easy to install as lifting pins and are sure to carry heavy components with perfect safety and reliability.

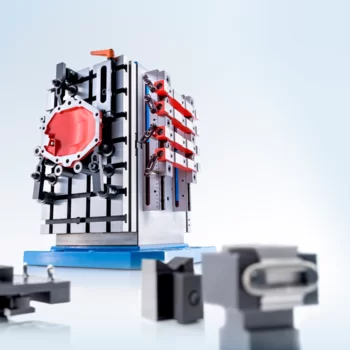

Load-handling devices are used wherever users need to fasten counterweights, transport components or change clamping elements or workpieces. High-quality lifting aids can be expected to deliver great carrying force and maximum safety, but should also offer easy installation as an added benefit. Easy installation minimises effort, eases the workload and shortens non-productive times during production. If the component to be carried already comes with a threaded hole, the new threaded lifting pins made by Erwin Halder KG represent the ideal solution for changing loads quickly and with perfect ease.

“Lifting aids such as eye bolts need to be screwed into the component and removed again. This takes up precious time that could have been used better for work that adds value. Other solutions require that you incorporate separate locating holes - which may or may not be possible for a specific component. By contrast, our threaded lifting pins utilise threads that already exist, streamlining the process significantly”, explains Bernd Janner, Sales Executive at Erwin Halder KG.

How does that work? Arranged at the bottom end of the high-strength pins are self-threaded segments that are matched to the corresponding thread sizes. The user can release the pins for easy installation with just a push of an aluminium press button that has been integrated below the movable shackle. The pin can then be easily inserted into the existing threaded hole. When the press button is released, the threaded segments engage in the thread of the component to be carried, securing the lifting element. A push of the press button is all it takes to release the segments again. To keep the user from pushing the press button inadvertently and releasing the threaded lifting pin at the wrong moment, the shackle is equipped with a locking stud.

What is more, the threaded lifting pins offer extreme carrying force. The maximum lifting capacity can range up to 840 kg – depending on the model and with up to five times the safety. Their exceptional break resistance has been certified by TÜV Süd. Moreover, they are also CE-compliant.

The threaded lifting pins are available in two material options: One is made of steel heat treated with manganese phosphate while the other is constructed from precipitation hardened stainless steel (1.4542). Both versions are protected against corrosion and temperature-resistant up to 250°C. In addition, the lifting pin made from stainless steel is weather-resistant and thus perfectly suited for outdoor implementations. From stock, Erwin Halder KG makes these lifting elements available in thread sizes of M10, M12 and M16.

The new threaded lifting pins made by Erwin Halder KG are just as quick and easy to install as lifting pins and are sure to carry heavy components with perfect safety and reliability.

Downloads: